The NPFLEX-1000 white light interferometry (WLI) system delivers exceptional flexibility, measurement performance, and process insight for precision manufacturing operations aiming to optimize control. Its open-gantry architecture and 300-mm clearance between stage and objectives allow effortless measurement of nano- to macro-scale features across samples of varying shapes and sizes.

The one-click Advanced Find Surface™ feature streamlines operation and shortens time-to-result by combining auto-focus and auto-illumination, eliminating the need for manual surface registration before each scan. With its self-adapting USI measurement mode and intuitive VisionXpress ™ interface, the NPFLEX-1000 enables robust, high-accuracy metrology for industries such as automotive, medical devices, and additive manufacturing.

NPFLEX-1000 Features

Image Credit: Bruker Nano Surfaces and Metrology

- Compatibility with large parts and steep slopes reduces the need for sample preparation and broadens the range of accessible measurement surfaces per component.

- Easy operation enables users of all experience levels to achieve expert-level results.

- High-speed automated measurement and analysis routines significantly shorten time-to-result.

- A robust bridge architecture combined with integrated vibration isolation delivers long-term accuracy and reliability in demanding production environments.

Practical Advantages

With open-access sample loading and intuitive analysis software, users can characterize surface texture, finish, roughness, curvature, slope, and more, with sub-micron resolution.

Material-insensitive: Supports reflectivity from 0.05 % to 100 % and accommodates surface textures from flat to rough

Automation-ready: Fully customized measurement and analysis routines

Self-calibrating: Delivers maximum accuracy and repeatability

Unparalleled Profilometry for Roughness and Surface Texture

Why White Light Interferometry?

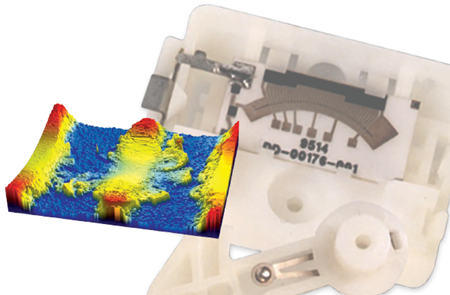

Additive-manufactured surface. Image Credit: Bruker Nano Surfaces and Metrology

Most non-contact areal profiler techniques depend on magnification, often requiring high-resolution objectives with short working distances to achieve optimal vertical resolution. In contrast, white light interferometry (WLI) uses interferometric objectives to reveal surface features through a moiré pattern that appears only at the point of focus.

Because white light has a limited coherence length, the moiré pattern's depth of field is restricted to about ±1 µm. This allows the focal plane to be determined within a few nanometers, making the technique independent of magnification. As a result, WLI maintains nanometer-level precision even with low-magnification objectives (e.g., 1×, 2.5×, 5×), offering several key metrology advantages:

-

Access to complex geometries: Long working distance objectives allow measurement of recessed or intricate areas without sacrificing vertical resolution

-

Improved usability and safety: The added clearance between the objective and sample surface simplifies targeting and reduces collision risk

-

Vertical surface measurement: A mirror can be introduced into the beam path to deflect the optical axis for precise sidewall profiling

-

Wide field of view: A single low-magnification scan covers up to 100 mm2, enabling rapid flatness checks and efficient defect detection

-

Extended coverage with detail: Stitching allows high lateral resolution to be maintained across broader areas

-

Consistent vertical resolution: All objective lenses deliver the same vertical precision, simplifying metrology planning and equipment budgeting

Surface-Independent Metrology for Application-Specific Solutions

The NPFLEX-1000 pairs a large form-factor gantry with fast time-to-result and high-quality data, even from non-expert users. Its open-access, durable bridge design, swivel head, and a range of objective lens options enable maximum flexibility in sample size and accurate measurement of high-slope surfaces.

Built for versatility, the NPFLEX-1000 is engineered to address roughness and surface texture measurement needs that commonly arise in precision machining QA/QC workflows across industries such as automotive, medical devices, and large-scale additive manufacturing. Typical QA/QC applications include:

Corrosion Monitoring

Image Credit: Bruker Nano Surfaces and Metrology

- Identify and quantify indicators of corrosion

- Automatically measure pit count, maximum width, depth, and volume

- Evaluate total volume loss in complex alloy systems

Surface Finish Quality Control

Image Credit: Bruker Nano Surfaces and Metrology

- Measure surface texture

- Correlate surface features with material properties

- Support improved control of manufacturing processes

Wear and Lifetime Assessment

Image Credit: Bruker Nano Surfaces and Metrology

- Quantify material loss over time

- Analyze peak-to-valley ratios

- Assess the directional characteristics of wear

Bore Cylinder Surface Texture

Image Credit: Bruker Nano Surfaces and Metrology

- Analyze sidewall roughness to assess lubrication and sealing performance

- Use rotational stitching to detect surface defects along the inner diameter

- Extract angular data from cross-hatch patterns for detailed characterization

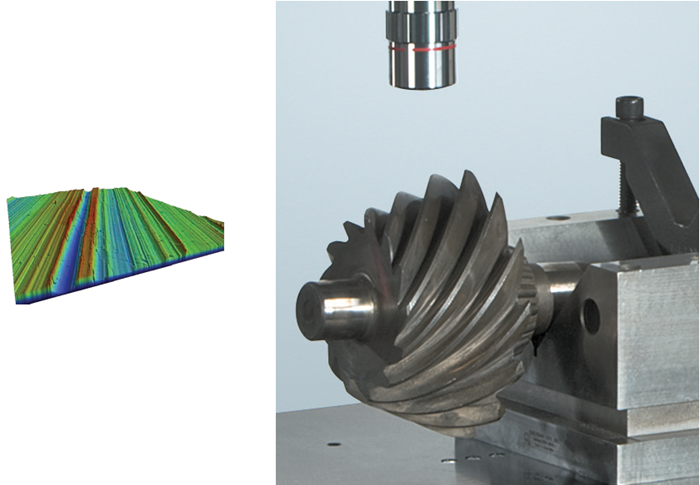

Gear Flank Roughness

Image Credit: Bruker Nano Surfaces and Metrology

- Measure the bearing function to evaluate real contact area

- Quantify tooth wear non-destructively through tribology testing

- Assess surface morphology and resistance after coating or treatment

Chatter Marks Analysis

Image Credit: Bruker Nano Surfaces and Metrology

- Inspect camshaft lobes for signs of chatter

- Quantify the periodicity of chatter marks

- Analyze how the texture of interfacing surfaces impacts part performance and potential failure

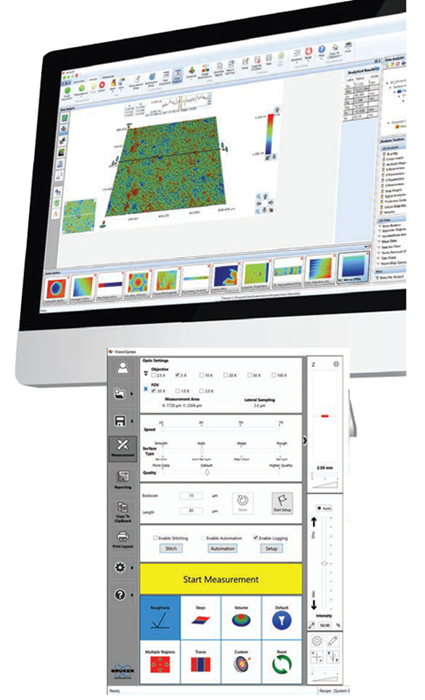

Optimal Performance and Ease of Use

Image Credit: Bruker Nano Surfaces and Metrology

The NPFLEX-1000 is designed to meet the needs of both R&D environments and high-throughput production lines. Its intuitive measurement and analysis tools enable users of all experience levels to achieve consistent, expert-level results quickly. For specialized tasks, the system supports fully customizable routines tailored to specific application requirements.

Powered by Vision64®, the industry’s leading graphical user interface for metrology, the NPFLEX-1000 offers a robust and user-friendly software experience. Key features include:

Advanced Find Surface for Effortless Setup

Ideal for multi-user environments, this feature combines autofocus with automatic adjustment of key illumination settings, such as LED ring light intensity, to deliver reliable measurements across a wide range of materials and surface types.

VisionXpress for Fast Routine Analyses

Users can choose the streamlined VisionXpress interface for routine tasks, the award-winning full-featured Vision64 interface for advanced configuration and automation, or the Advanced Production interface for fully automated operation with minimal user input, ensuring flexible support for diverse metrology workflows.

Universal Scanning Interferometry for Expert Results Every Time

3D Profile Showing µm Step. Image Credit: Bruker Nano Surfaces and Metrology

Sub-nm Roughness, Top and Bottom Surfaces. Image Credit: Bruker Nano Surfaces and Metrology

Bruker’s Universal Scanning Interferometry (USI) mode delivers highly accurate WLI measurements across a broad range of surface types. Unlike systems that require switching scanning modes or objectives, USI uses adaptive surface intelligence to automatically adjust algorithm parameters, optimizing results for surface textures with varying contrast, intensity, and height, all within a single field of view.

Capable of measuring transparent to opaque surfaces with a vertical range up to 120 µm, USI mode intelligently detects surface characteristics and applies the most suitable metrology approach. This makes it one of the most robust and user-friendly methods available for complex areal surface measurements.

Designed for Extreme Flexibility

CNC - milled part. Image Credit: Bruker Nano Surfaces and Metrology

The NPFLEX-1000 is engineered for high productivity across both lab and factory environments. Its large-format gantry and swivel head enable access to challenging orientations on large or complex parts.

Integrated vibration isolation and a self-calibrating laser reference ensure consistent performance and reliability in any setting. A range of optional accessories allows the system to be tailored to your specific samples and applications.

Open Gantry and Swivel Head Access Difficult Surfaces

A generous 300 mm clearance between the stage and objectives accommodates a wide variety of custom mounts and fixtures, such as universal sample holders and vacuum wafer chucks. This design allows for quick part changes and minimal setup, supporting efficient measurements across diverse surfaces and part geometries.

The swivel head enhances accessibility, enabling repeated inspection of features like sidewalls, beveled edges, and angled surfaces without repositioning the sample.

Objective Lens Innovations Extend Viewable Areas

Long working-distance objectives (up to 34 mm) ensure safe lens-to-sample spacing while supporting a broader range of sample types. The bore-scope objective enables precise 3D inspection of cylindrical surfaces, capturing data up to 150 mm deep inside bores and cylinders.

When combined with the theta rotating stage, this configuration supports automated 3D inner-diameter stitching. Additionally, a fold mirror allows for non-destructive measurements along steep sidewalls (up to 70 °) and within the interior features of bowl-shaped or cylindrical parts.

Motorized Stages Maximize Maneuverability

Fold mirror on objective. Image Credit: Bruker Nano Surfaces and Metrology

Bore-scope objective. Image Credit: Bruker Nano Surfaces and Metrology

Motorized theta rotating stage. Image Credit: Bruker Nano Surfaces and Metrology

Motorized phi rotating stage. Image Credit: Bruker Nano Surfaces and Metrology

The NPFLEX-1000 enables fully automated movement to any location on the sample, without the need for remounting.

- Automated XY stage with 10 mm Z travel for efficient batch review of trays

-

Rotational stage with optional chuck for secure fixture handling

-

Theta rotating stage for sample rotation

-

Phi rotating stage for vertical sample rotation

-

Phi roller stage for automated positioning and rotation of small cylindrical samples

Self-Calibrating Laser Reference Ensures Stability

The NPFLEX-1000’s self-calibrating capability ensures excellent reproducibility, even when environmental conditions are not tightly controlled. Its built-in reference signal laser interferometer continuously adjusts for temperature changes, compensating for external influences to deliver consistently accurate and repeatable measurements, ideal for applications requiring long-term stability.

NPFLEX-1000 Specifications

Source: Bruker Nano Surfaces and Metrology

| . |

. |

| Measurement Modes |

PSI, USI, VSI, Optional Film |

| Max. Scan Range |

≤10 mm |

| Vertical Resolution¹ |

<0.01 nm |

| Lateral Resolution |

0.38 μm minimum (Sparrow criterion)

0.13 μm (with AcuityXR®) |

| Step Height Accuracy² |

<0.75 % |

| Step Height Repeatability |

<0.125 % one sigma repeatability |

| Max. Scan |

≤122 μm/sec (with laser references) |

| Sample Reflectivity |

0.05 % to 100 % |

| Sample Size |

350 mm × 304 mm × 304 mm (H × D × W);

249 mm H with automated stage |

| Sample Weight |

45 kg (77 kg without standard stage) |

| XY Sample Stage |

300 mm automated |

| Z Focusing |

249 (350 mm without automated stage) |

| Optical Metrology Module |

Patented dual-LED illumination |

| Objectives |

Parfocal: 2.5X, 5X, 10X, 20X, 50X, 100X, 115X; LWD: 1X, 2X, 5X, 10X;

TTM: 2X, 5X, 10X, 20X; Bright Field: 10X;

Single-objective adapter; Optional motorized five-position turret |

| Available Zoom Lenses |

0.55X, 0.75X, 1X 1.5X, 2X auto-sensing modules |

| Camera |

5 MP monochrome with 1200 × 1000 data array; Optional color camera |

| Software System |

Vision64 and VisionXpress on Windows 10 LTS 64-bit OS |

| Software Packages |

AcuityXR; Advanced PSI; Automatic Pattern Alignment; MATLAB; Multiple Region Analysis; Optical Microlens Analysis; Production Mode; SDK; TCP/IP; SureVision; Vision64 Map™ |

| Reporting Languages |

English; German; French; Italian; Spanish; Japanese; Chinese; Polish; Korean; Brazilian Portuguese; Russian |

| Automation |

Auto-focus; Auto-intensity; Auto-saving; Auto-stitching;

On-fly analysis; Scattered and grid automation; Recording in database |

| Calibration |

Optional auto and continuous internal laser signal |

| System Footprint |

1717 mm × 772 mm × 914 mm (H × D × W) |

| Weight |

478 kg |

| Warranty |

12 months |

| Certification |

CE-Certification |

1 As demonstrated by taking the one sigma Sq value of 30 PSI repeatability measurements on an SiC reference mirror.

2 Absolute accuracy for step heights 8 μm and higher.